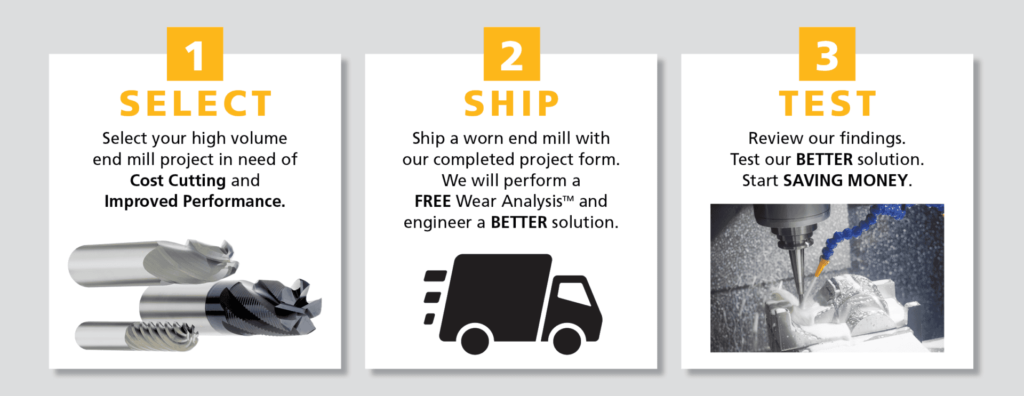

Building A Better End Mill Is As EASY As 1, 2, 3…

Want to Talk to an Expert First? No Problem.

Have a no-pressure conversation with our expert team. Worst case, we’ll point you in the right direction!

Phone: 800-345-0210 | Email: [email protected]

If you are ready to start saving, download the End Mill Project Form or submit and print your form below