During the manufacturing of an end mill there are various operations that create the necessary geometries which produce the final product. In this example we are teaching about Gash and Web Thickness. Without careful attention during the manufacturing process this is an area of the end mill that can easily be out of spec resulting in poor tool performance.

Proper Gash & Web Thickness:

The photo above shows an End Mill with Proper Gash and Web thickness. You’ll notice that the primary clearance intersects to a minimal point.

The exact ideal measurement of the web thickness will depend on the diameter of the end mill itself.

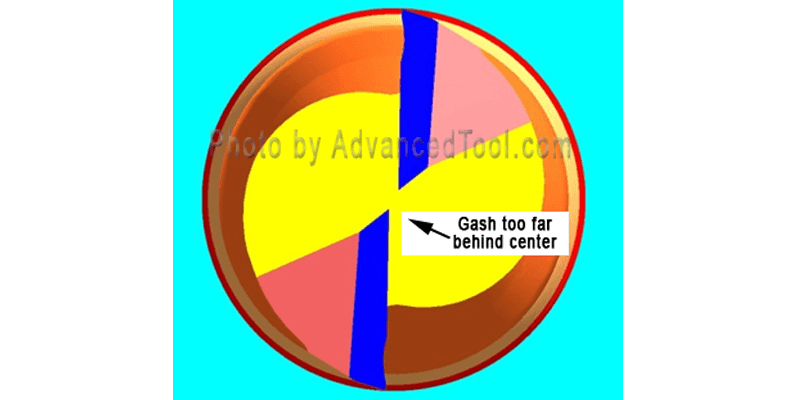

Improper Gash & Web Thickness:

This example below demonstrates and End Mill with the gash being too far behind center causing the web thickness to be non-existent.

Results: This can cause the tool to be weak and break during operation.

This next example demonstrates an End Mill with the gash being too far ahead of center causing the web thickness to be too large.

Results: This creates an area along the end of the end mill that will not cut. This causes the end mill to work harder, requiring more CNC machining power. In an end cutting milling operation the tool will act dull even if it’s not.

Creating perfect end mills every single time takes dedication and a thorough in-process inspection process. At Advanced Tool Inc, we will not ship an imperfect tool to our customers.