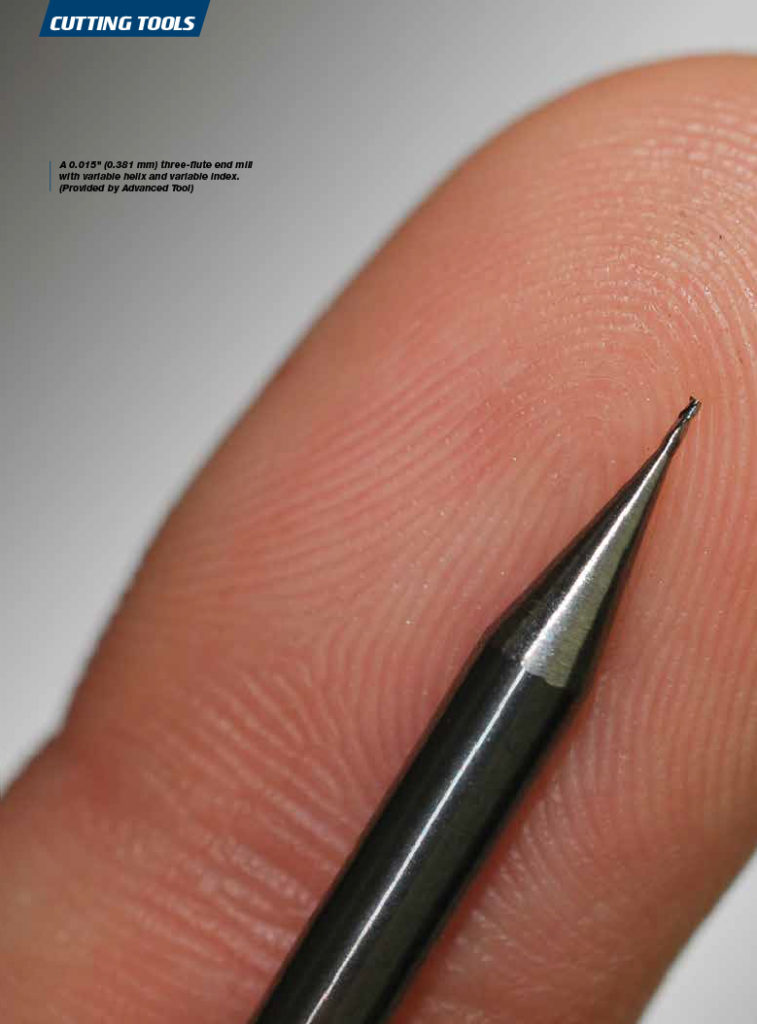

The smaller your micro end mills go the more difficult it is to get precision complex geometry. At Advanced Tool Inc, you will never see sloppy or mediocre geometry.

High Performance Micro End Mill Manufacturing

We begin by carefully crafting and formulating each element in the production of a micro end mill, and commit to using only the highest quality substrates and coatings. Micro tool edge geometries may not be visible to the naked eye, but they’re critical to the manufacturing process. Diameters available in every increment of .001”; square end, ball end, corner radius, bi-radial and custom geometries.

Ramp up your micro milling application with a tailor made custom end mill

• All miniatures ground with primary and secondary relief angles

• 1/8” Shank x 1–1/2” OAL, at 50pcs or more—no one is more competitive!

• Any configuration made to order—capabilities down to .005” Dia.

• 2 Flute: Square End & Ball End—select sizes stocked and ready to ship

Nationally recognized Micro Manufacturing magazine published the following article Identifying Proper Micro-Endmill Geometry, written by Sherry DePerno, President & CEO of Advanced Tool Inc

Start a Project with Wear Analysis™

Wear Analysis™ looks at the mill you are currently using. This is a 21 point inspection of edge wear and breakdown for the improvement of cutting tool geometry. This tells us exactly how you are using the end mill, how much of the mill you are using, what’s working and what’s not.

Talk to an Expert

Ph. 800-345-0210 | 315-768-8502

[email protected]