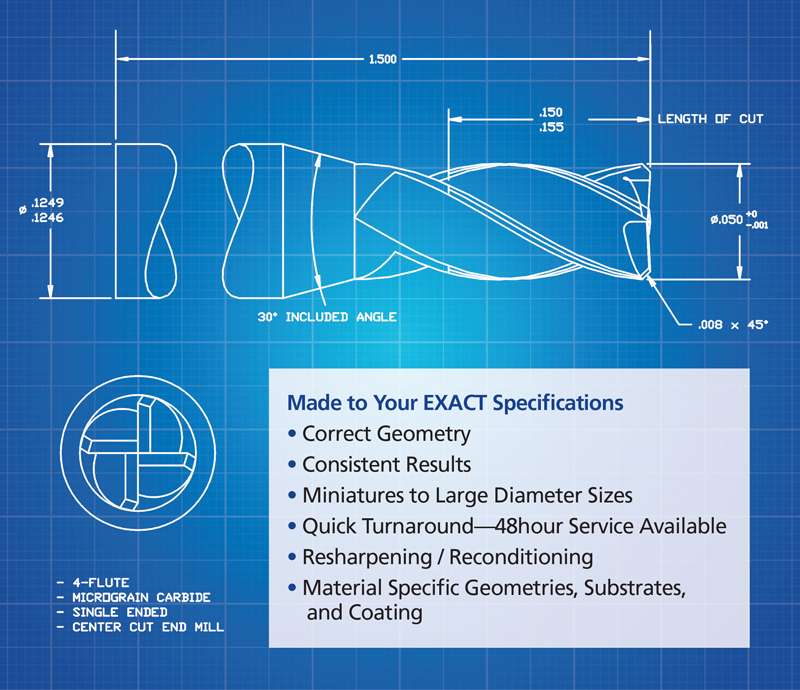

Blueprint End Mills Made Your Way. The Same Every Time. Consistent Quality Production Manufacturing that does not deviate.

Geometry

Geometry for your toughest materials designed the way you machine.

Substrate/Raw Material

Unique raw material grades available to balance toughness and fracture resistance for stainless, titanium, steels, aluminum and more. We let you decide who’s material you want to try.

Coating Recipes & Coating Technology

Tool Coating is the fasting moving area of cutting tool manufacturing. We partner with world leaders in innovation and technology to bring you the very best options as soon as they become available. Our customers test coating options before they are available in anyone’s catalog.

Think there could be a fit?

Have a no-pressure conversation with our expert team. Worst case, we’ll point you in the right direction!

Phone: 800-345-0210 | Email: [email protected]