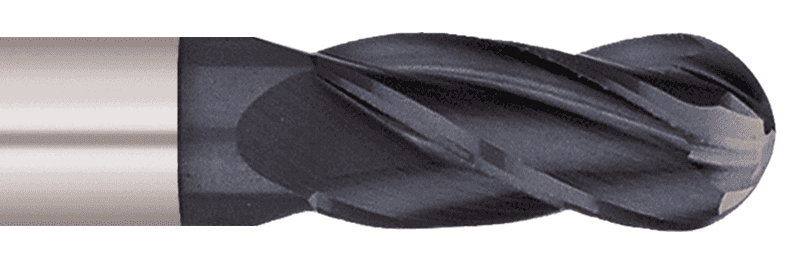

Understanding End Mill Coatings

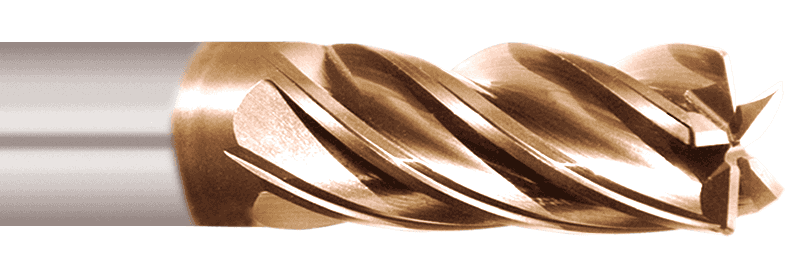

The Purpose of Coatings: Extend Tool Life, Wear Resistance, minimize built up edge, Faster Speeds & Feeds, increase productivity.

The most important thing to understand about coating is that it’s NOT just about the picking the right coating selection (AlCrN, AlTiN, TiAlN, TiCN, TiB2, ZrN, etc). It’s equally important to pick the right process of applying the coating, along with pre and post treatments and coating thickness.

We work directly with the Coaters to design the perfect chemistry, hardness, thickness and finish for optimum cutting performance in your application.

The purpose of coatings: Extend Tool Life, Wear Resistance, minimize built up edge, Faster Speeds & Feeds, increase productivity

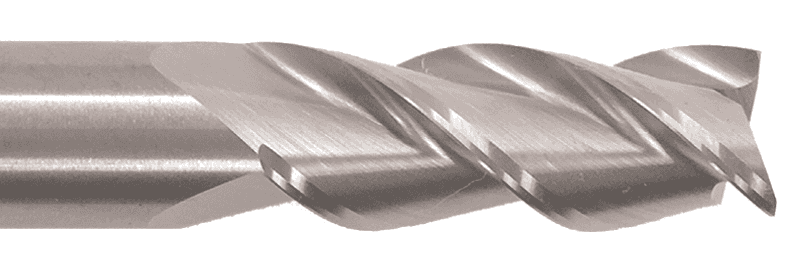

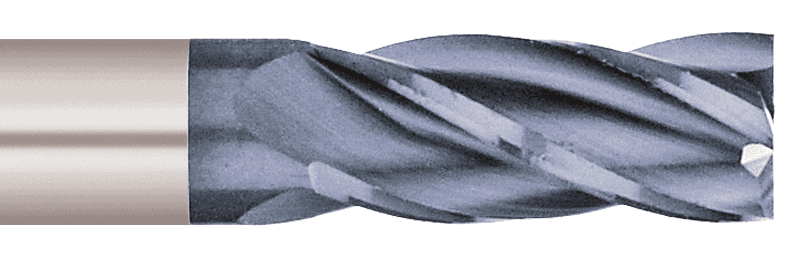

Application Technology choices:

• Physical Vapor Deposition (PVD): thin, better edge toughness, smoother

• Arc Evaporation (ARC)

• High-power impulse magnetron sputtering (HiPIMS) – ultra dense coatings

• Chemical Vapor Deposition (CVD): thick, wear resistant – older technology still used in indexable tooling, but not round shank such as end mills

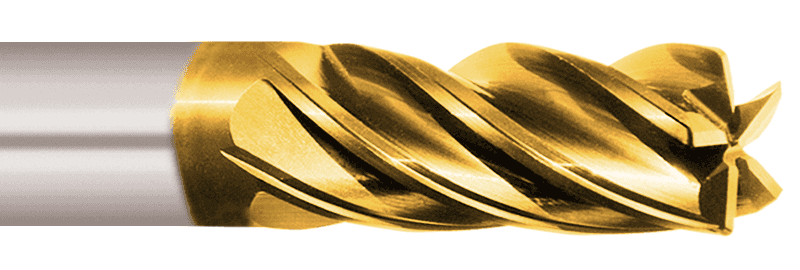

Just some of the chemical compositions

• Titanium Aluminum Nitride (TiAlN)

• Aluminium Titanium Nitride (AlTiN)

• Titanium Carbonitride (TiCN)

• Titanium Nitride (TiN)

• Aluminum Chromium Nitride (AlCrN)

• Titanium DiBoride (Tib2)

• Zirconium Nitride (ZrN)

• Diamond

• Aluminium Oxide (Al2O3)

Thickness • Finish • Pre and Post Treatments • Edge Honing